Propylene recovery and N₂ purification in PP plant

Problem:

The vent gas from resin degassing bin typically contains approximately 10+%(V) propylene and 70-85%(V) nitrogen. For a 300 KTA PP plant, the hydrocarbons and nitrogen losses in the vent gas are close to US$ 1.2 -2.0 million per year. Eurofilm's patent technologies have been applied successfully for the following processes:

• Innovene of INEOS (UK)

• Novolen of Lummus Novolen (GER)

• Horizone (Chisso) of JPP (JP)

• Unipol of Dow (USA)

Performance:

• Propylene recovery: 90-97%

• N2 recovery: 70-80%

• N2 purities: 95-99+ mol%

Operating characteristic:

• Min. operating temperature: lower to -30°C

• Max. operating pressure: up to 25 barg

Scope of supply:

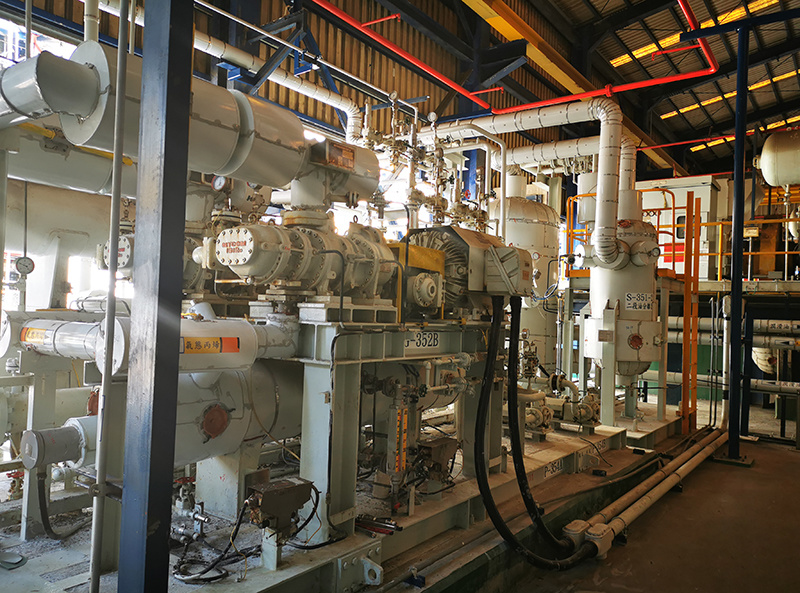

• Compressor

• Dehydration (upon request)

• Condenser refrigeration (upon request)

• HCs membrane unit

• H2 membrane unit

Standards:

• Compressor: API 619

• Lubrication, Shaft-sealing and Oil-control Systems and Auxiliaries: API 614

• Machine Protection Systems: API 670

• Mechanical Seals and Supply Systems: API 682

• Pressure vessel: ASME, TEMA

• Electrical: IEC or NEC

• ISO 9001 certified process

• Hazardous (ATEX/Class Div2)

References:

Location: Japan

End user: Mitsuishi Chemical

Capacity of PP: 300,000 tons/year

Technology: Amoco/JPP

Propylene recovery: ≥90%

N2 purities: >99 mol%

Location: Nigeria

End user: Dangote

Capacity of PP: 830,000 tons/year

Technology: Innovene/INEOS

Propylene recovery: 97-99%

N2 purities: ≥98.5 mol%

N2 recovery: 70-80%

Location: Taiwan, China

End user: FCFC

Capacity of PP: 300,000 tons/year

Technology: Chisso/JPP

Propylene recovery: >95%

N2 purities: >99 mol%

N2 recovery: >60%

Location: China

End user: Exxon-Mobil/Aramco

Capacity of PP: 550,000 tons/year

Technology: Novolen/Lummus

Propylene recovery: 92-98%

N2 recovery: 60-80%

Location: China

End user: Shenhua

Capacity of PP: 600,000 tons/year

Technology: Novolen/Lummus

Propylene + ethylene recovery: ≥92%

N2 recovery: 60-80%